Here Are 9 Best High Productions Double Capacity Color Coated Corrugated Iron Roofing Roof Sheet Making Roll Forming Machine Manufacturer Price In India | Tin Coating Patra Banane Ki Machine

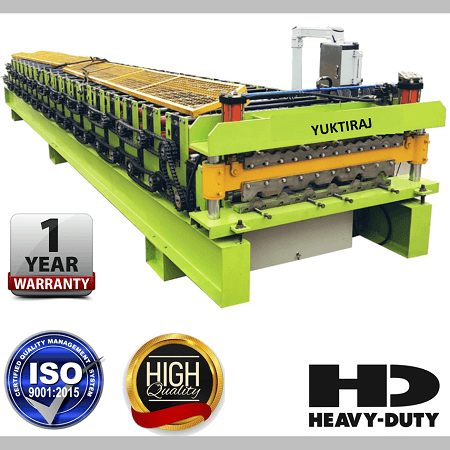

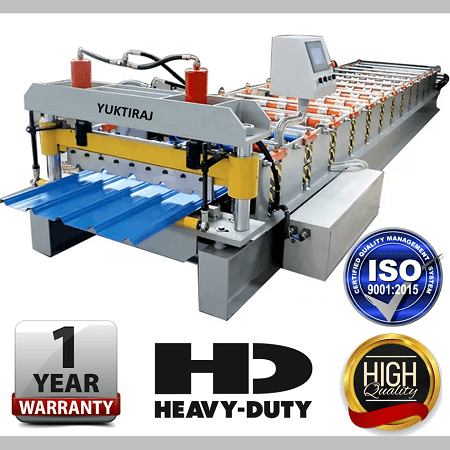

Model:- Yukti 173 Top Class Corrugated Galvanized Steel Roofing Sheets Manufacturing Machine | coating patra machine low price.

welcome all, Corrugated Galvanized Steel Roofing Sheets Manufacturing Machine | coating patra machine with low price. is mainly used to produce various types of metal roof sheet required for factory, bus stations, stadiums, exhibition pavilions, urban buildings, ware house, school etc. Galvanized Steel Roofing Sheets has strong durability, it’s almost impossible to be damaged also steel roof is fast and economical way to building contractions which greatly saves time also labor costs. This machine Model Yukti 173 is high end technology that boosts productions capacity save power. Famous delta Japan Brand plc control, quality is guaranteed. Full Automatic Computer Control make easy and simple to operation. Machine roller also shaft is produced by exact demands also control. Machine quality is durable also long service life. Finished sheet is smooth and glossy no crashes come out 100% finished work. The finished steel roof sheet after rolling is smooth exclusive of burrs also not easily deformed. this machine come with roll holder, roll cutter, sheet keeping table, ready to work no need for extra any machine. Save labor cost boost production. Its high size Corrugated Galvanized Steel Roofing Sheets Manufacturing Machine input roll size is 1450mm its high end. We offer all India free delivery. And 365 days nonstop support. For more watch video and click on product catalogue button.

Technical Details :-

Feeding Material:- Ppgl / Aluminium / Glgl / Colour Coated Roll. Thickness Of The Plate:- 0.3--0.8mm. Diameter Of The Axle:- 70mm. Rolling Stages:- 16 Stages. Productivity:- 8 -16m/Min. Total Power:- 5.5kw Machine Motor + 4kw Pump Station Motor. Voltage:- 380V 50hz 3phase. Base Frame:- 350H Steel. Side Board Thickness:- 18mm. Cutting Blade:- Cr12 With Heat Treatment. Cutting System:- Hydraulic Cutting System After Forming. Control Cabinet:- PLC Frequency Changer In It (Delta Japan Brand). Input Roll:- 1450mm. Output Sheet:- 1220mm. Dimension(L*W*H):- 8000*1750*1750mm. Cutting blade material:- Cr 12 High-Grade Steel. Weight:- Around 5000 kg. Warranty:- 1 Year Provided By Yuktiraj Pvt Ltd. Service And Support:- Online. Shipping:- All India Free. Training:- By Online Video. Usage / Application:- roll forming and roof sheet making | tin coating patra banana ke liye.

Price:- 2397000 ₹ + 431460 ₹ 18% Gst Total Payable 2828460 ₹.

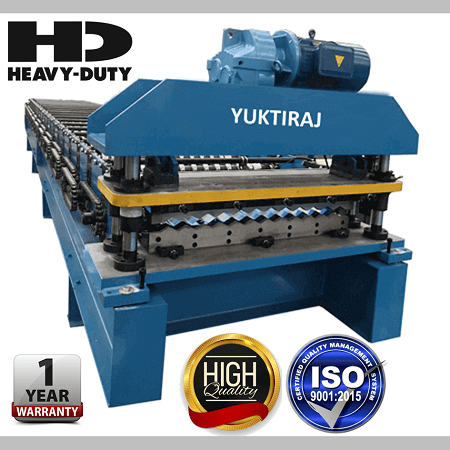

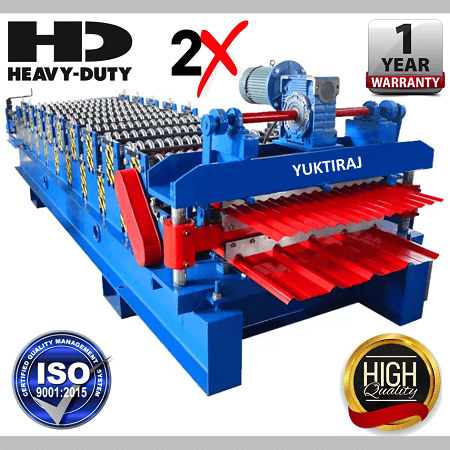

Model:- Yukti 62 High Productions Double Capacity Corrugated Iron Roofing Roof Sheet Making Machine Best Price In India | tin patra banane ki machine.

Hi, everyone welcome in Yuktiraj Pvt Ltd. We are india’s leading b2b company. We offer all business machine in reasonable price and great support 365 days on. If you want start corrugated iron roofing sheet making business then its good news you select right business. corrugated iron roofing sheet have strong demand in Indian market. Here we are selling Double Capacity Corrugated Iron Roofing Roof Sheet Making Machine | tin patra banane ki machine. This machine is high productions rate low electricity use and almost low maintenance. High quality for long time and heavy duty. Double layer roofing tile machine. can produce 2 type sheets, The input material are both 1000 mm width with thickness 0.3-0.8 mm. Machine speed is super fast 8-16 m per minute. With pre cutting system and double inches chain. This machine cheaper also stable orations.

Technical details.

Tile Type:- Colored Steel. Production

Capacity:- 8-16 m/min. Voltage:- 380V

50Hz 3phases. Weight:- 3.0 T. Rolling thickness:- 0.3-0.8mm. Feeding width:- 1000mm. Shaft material:-

45# Steel. Cutting type:-Hydraulic Cutting. Roller material:- 45#steel Chrome Plated. Dimension(L*W*H):-7500mm*1400mm*1500mm. warranty:- 1 year. Support:-

online. Usage / Application:- roll forming

and roof sheet making | tin coating patra banana ke liye.

Price:- 2797000 ₹ + 503460 ₹ 18% Gst Total Payable 3300460 ₹.

Model:- Yukti 165 Eco Corrugated Iron Roofing Roof Sheet Making Machine Best Price In India | Roll forming machine low price in india.

Hi, everyone welcome in Yuktiraj Pvt Ltd. We are india’s leading business solutions company. We offer all business machines in reasonable price prompt support 365 days always on. If you want start corrugated iron roof sheet making business then its fine news you select right business. Corrugated iron roofing sheet have high demand in Indian market. Here we are selling Eco Corrugated Iron Roofing Roof Sheet Making Machine | roll forming machine low price in india. This machine is high productions rate low electricity use also almost low maintenance. High quality for long time and heavy duty. single layer roofing tile machine. can produce 1 type sheets, The input material are 1000 mm width with thickness 0.3-0.8 mm. Machine speed is super fast 8-10 m per minute. With pre cutting system. This machine cheaper also stable orations. The machine is used to construct external roofing also wall panels of houses and interior panels otherwise ceilings to improve the appearance of the roof or walls also durability.

Technical details.

Tile Type:- Colored Steel. Production Capacity:- 8-10 M/Min. Voltage:- 380V 50Hz 3phases. Weight:- 1.5 T. Rolling Thickness:- 0.3-0.8mm. Feeding Width:- 1000mm. Shaft Material:- 45# Steel. Cutting Type:-Hydraulic Cutting. Roller Material:- 45#Steel Chrome Plated. Dimension(L*W*H):-5500mm*1400mm*1500mm. Shaft Diameter:-70mm. Warranty:- 1 Year. Support:- Online. Warranty Provider:- Yuktiraj Pvt Ltd. Usage / Application:- roll forming and roof sheet making | tin coating patra banana ke liye.

Price:- 1600000 ₹ + 288000 ₹ 18% Gst Total Payable 1888000 ₹.

Model:- Yukti 300 Roll forming roofing profile sheets sheet manufacturing machine best price list we are leading manufacturers get complete plant cost.

Hi, friends lovingly welcome to YUKTIRAJ PVT LTD. Model Yukti 300 is high end very big and strong double deck roof sheet Roll forming making machine, this machine makes two kinds of profiles to save your labor cost and boost production, and overbank your competitor. Roofing sheet manufacturing is the best business in India just you need a stronger machine to become successful low price machine means buying everyday headaches. Lower price machines never produce high-quality products and low-quality products are sold in the market. If you have no details or ideas about this business then feel free to contact us we give roofing sheet manufacturing plant cost and machine price. Operating a Roofing roll forming machine is very simple with a few clicks to enter required orders on the touch screen, then the intelligent PLC system will control the machine and produce the final roof sheet as you want. Feature of our roofing sheet manufacturing machine: 1. our roofing sheet manufacturing machine can use galvanized steel sheets, colored armor plates, or aluminum plates as material plates. 2. Controlling by computer PLC display, the operation is easy simple and humanized. 3. Organization is steady also reliable endurable maintenance-free. 4. Scratch free very smooth production. 5. Less noise environment friendly. 6. Low maintenance, high output. 8. Advantages of structure that save many working spaces. 9. Able to accept high hardness around G550. 10. This is a high-end double-layer roofing sheet manufacturing machine with the best price. YUKTIRAJ PVT LTD Advantage: 1. we have rich experience in manufacturing import export roofing sheets and designing the machine. 2. we have excellent workers, a strong selling team, and exquisite dedicated technology. 3. We can make all designs and kinds of roofing sheet manufacturing machines according to the customer’s request. 4. We will provide technical support for the whole machine life and free onsite training and free shipping for all India-free installations. Successful business owners never use cheap price machines stronger machines may be success cheaper machines maybe fail. Don’t buy a cheaper machine it's only headaches. Roll forming roofing profile sheets sheet manufacturing machine means YUKTIRAJ PVT LTD only. We are the leader roll forming machine manufacturers with the best price in India. Click below the product catalogs button.

Technical Details

Model:- Yukti- 300. Suitable Material:- Aluzinc/Galvanized Steel/Colored Steel Coil/G550. Feeding Width:- 1450MM. Roller:- 45# Forged Steel, With Hard Chrome Plating. Machine Size:- About 9200*1700*1500mm. Motor Power:- 5.5 Kw. Pump Station Power:- 4kw. Thickness Of Raw Material:- 0.3-0.8mm. Productivity:- 10- 15m/Min. Diameter Of Shaft:- ¢75mm. Forming Steps:- 20steps. Weight:- Almost 6 Ton. Voltage:- 380V 50hz 3phases. Side Plate Thickness:- 16mm. Structure Of Machine:- 350mm "H" Steel Welding. Transmission Way:- 1 Inch Chain Drive. Automatic Control System:- Delta PLC Made In Japan. Reducer:- 4# Planetary Ration1:59. Cutting Blade Material:- Cr12. Control System:- Japan Brand Delta PLC Control System With Touch Screen. Warranty:- One Year. Support:- Online. Installation:- On Site Free. Shipping:- All India Free. Training:- Free Onsite One Days. Usage / Application:- roll forming and roof sheet making | tin coating patra banana ke liye.

Price:- 4200000 ₹ + 18% GST 756000 ₹ Total Payable 4956000 ₹.

Model:- Yukti 301 Big size False ceiling channel roofing roof profile sheet roll forming making and cutting machine best price | patra making machine low price in india.

Hello, friends warmly welcome to YUKTIRAJ PVT LTD. Model Yukti 301 is the best false ceiling channel roofing roof profile sheet roll forming making and cutting machine lowest price. This roof sheet making machine can roll from metal roofing sheets. After the roll is formed by this profile sheet making machine, the surface will be very smooth also beautiful without any scratch the surface and the machine are more perfect (generally scratch is a major issue many roofing sheet manufacturing machines fail to produce scratch free). This roofing sheet manufacturing machine Fully Automatic Control System with japan made PLC. Easy operation Key in the length also quantity on the control panel. Precise forming High solid forming stand guarantees the goods also uniform high quality of final produced. Roofing sheet roll forming machine with Draw knife that can make the last board without manual cutting also clutch that can control the number plate. Roof sheet-making machine Advantage:- 1. Super power saving. 2. Essay to operate and maintain. 3. Fully automatic operation and large output. 4. Low operating cost Stable working. 5. Lengthier life working. 6. Less noise environmental protection. 7. Process hard roll easily. 8. Advantages structure low space requirement 9. Reduce Lobar cost one or two Lobar enough. Made in Japan plc control. 10. Roofing sheet roll forming machine low price. 11. Made after full research and development no any (deshi jugad) used. 12. High end almost 4 feet width sheet output. Why only we are best for roofing sheets manufacturing machines? YUKTIRAJ PVT LTD is an Indian leading roll forming machine professional manufacturer and import Export Company we sell this machine to 30 countries. We have obligated ISO quality certification. We can produce the best quality roofing sheet manufacturing machine for you. We have high-quality professional teams, a strong technical force, skillful talents, strong and independent research and development capabilities, advanced production equipment also a great sales service system. We provide you with roofing sheet manufacturing plant costs. We provide you best marketing strategy and business manners. All India free delivery onsite installations and operation training. If you want success roofing sheets manufacturing business then start with a stronger machine. Every business foundation is based on a machine low price machine means a higher chance to fail stronger machine higher chance of success. If you need any type of assistance regarding then feel free to contact us. Beware of the duplicated machine. if you buy other low-price profile sheet-making machines then you will have headaches every day because of horrifying performance. its best patra making machine low price in india. Click below the product catalogs button.

Technical Details

Model:- Yukti- 301. Suitable Material:- Aluzinc/Galvanized Steel/Colored Steel Coil/G550. Feeding Width:- 1450MM. Roller:- 45# with 0.05mm chrom. Machine Size:- About 9200*1700*1500mm. Motor Power:- 5.5 Kw. Pump Station Power:- 4kw. Thickness Of Raw Material:- 0.3-0.8mm. Productivity:- 8-15m/Min. Diameter Of Shaft:- ¢75mm. Forming Steps:- 20steps. Weight:- Almost 6 Ton. Voltage:- 380V 50hz 3phases. Side Plate Thickness:- 16mm. Structure Of Machine:- 350mm "H" Steel Welding. Transmission Way:- 1.5 Inch Chain Drive. Automatic Control System:- Delta PLC Made In Japan. Reducer:- 4# Planetary Ration1:59. Cutting Blade Material:- Cr12. Control System:- Japan Brand Delta PLC Control System With Touch Screen. Warranty:- One Year. Support:- Online. Installation:- On-Site Free. Shipping:- All India Free. Training:- Free Onsite One Days. Usage / Application:- roll forming and roof sheet making | tin coating patra banana ke liye.

Price:- 2700000 ₹ + 18% GST 486000 ₹ Total Payable 3186000 ₹.

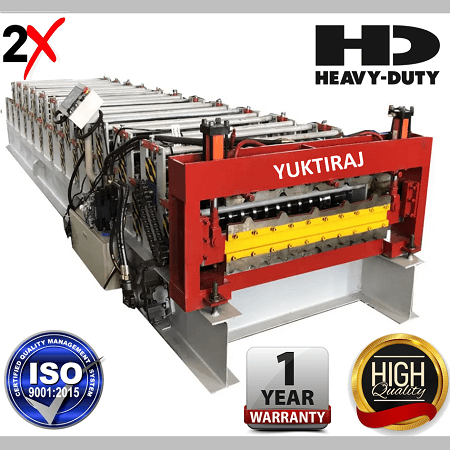

Model:- Yukti 302 Double layer Roll forming roofing profile sheets sheet manufacturing machine best price list we are leading manufacturers get complete plant cost.

Hello, friends, are you serious to start roofing profile sheets manufacturing? If yes. Then you are in right place we sell all types of Roll forming roofing profile sheet manufacturing machines best price. Model Yukti 302 double layer big size and hard Roll forming machine high reputation for designing high-quality, high-speed, safe also cost-effective The sheet produced is smooth and beautiful and durable. We design and make the best roofing profile sheet manufacturing machine, we took Indian quality standards. very easy to operate. We achieve that the machine capacity is double of your competitors. We select the best material and components globally famous electrical components and adopt our 4+ year’s experience that makes machines perfect work and longer life. Roofing profile sheet manufacturing machines are equipped with PLC control to ensure high accuracy also easy operation. The Roof sheet made by our double-layer roofing roll forming machine for roof panels has a beautiful appearance also bright color. PLC control is two optional control modes, automatic also manual By automatic mode, then this machine can realize fully automatic working. With our extraordinarily designed program, the human-computer interface is very simple and easy to be adopted by any level of the operator. We test the hardness also speed of the machine parts to ensure the high-speed also stable operation of the roll forming machine and improve work efficiency. Why we are best for roofing profile sheet manufacturing machines? Here is some valid point to note. 1. We can research also the development, manufacturing, and sale of a standard we can’t make any (deshi jugad) machine we need to mention standard because sell in more than 30 countries. 2. We could send a technician to your city to install machine no cost. 3. We offer all India free shipping. 4. We also provide technical training on-site at no cost. 5. We are ISO certified Pvt ltd company, not any firm or LLP. 6. We have a complete after-sales service dedicated system without worries. 7. We teach you the best marketing strategy. If you want success roofing sheets manufacturing business then start with a stronger machine. Every business foundation is based on a machine low price machine means a higher chance to fail stronger machine higher chance of success. If you need any type of assistance regarding then feel free to contact us. Beware of the duplicated machine. if you buy other low-price profile sheet-making machines then you will have headaches every day because of horrifying performance. Click below the product catalogs button.

Technical Details

Model:- Yukti- 302. Suitable Material:- PPGI. Feeding Width:- 1450MM. Roller:- 45# Forged Steel, With Hard Chrome Plating. Machine Size:- About 9200*1700*1500mm. Motor Power:- 7.5 Kw. Pump Station Power:- 5.5 kw. Thickness Of Raw Material:- 0.3-0.8mm. Productivity:- 8- 15m/Min. Diameter Of Shaft:- ¢75mm. Forming Steps:- 20steps trapezoidal 18steps corrugated. Weight:- Almost 6 Ton. Voltage:- 380V 50hz 3phases. Side Plate Thickness:- 16mm. Structure Of Machine:- 350mm "H" Steel Welding. Transmission Way:- 1.2 Inch Chain Drive. Automatic Control System:- Delta PLC Made In Japan. Reducer:- 4# Planetary Ration1:59. Cutting Blade Material:- Cr12. Warranty:- One Year. Support:- Online. Installation:- On Site Free. Shipping:- All India Free. Training:- Free Onsite One Days. Usage / Application:- roll forming and roof sheet making | tin coating patra banana ke liye.

Price:- 3900000 ₹ + 18% GST 702000 ₹ Total Payable 4602000 ₹.

Model:- Yukti 303 best Corrugated Roofing Sheet roll forming machine colour coated galvanized steel IBR roofing sheet making machine | coating patra machine low price in india.

Hello, friends, Model Yukti 303 best Corrugated Roofing Sheet roll forming machine color coated galvanized steel IBR roofing sheet making machine for sale in India at a low price | coating patra machine low price in india. The Corrugated Roofing Sheet roll forming machine is composed of the Frame, hydraulic station, PLC control system, and automatic shearing system. The roof sheets produced are flat and beautiful in appearance, uniform in paint pattern, and are widely used in industrial also civil buildings, such as houses, warehouses, hangars, gymnasiums, garages, exhibition halls, theaters, and other room surfaces and walls. The color-coated galvanized steel IBR roofing sheet-making machine adopts high-level automatic control software to realize production information management. The whole unit automation control system adopts a highly included network, which makes the computerization system have greater performance. It also has the advantages of easy operation, easy maintenance and debugging, and easy to operate. This machine is the high segment in cheap price high quality professional looking appearance not fancy. YUKTIRAJ PVT LTD is the top leader in roof sheet-making machines in India market. Click below the product catalogs button for all details.

Technical Details

Model:- Yukti- 303. Suitable Material:- Galvanized Steel/Colored Steel Coil/G550. Feeding Width:- 1250MM. Roller:- 45# steel forged. Machine Size:- L*W*H 5.3m *1.45m *1.5m. Motor Power:- 3 Kw. Pump Station Power:- 3kw. Thickness Of Raw Material:- 0.3-0.8mm. Productivity:- 8-15m/Min. Diameter Of Shaft:- ¢70mm 45# steel forged. Forming Steps:- 14steps. Weight:- Almost 2 Ton. Voltage:- 380V 50hz 3phases. Side Plate Thickness:- 14mm. Structure Of Machine:- 250 "H" Steel Welding. Transmission Way:- 0.6 Inch Chain Drive. Automatic Control System:- Delta PLC Made In Japan. Reducer:- 4# Planetary Ration1:59. Cutting Blade Material:- Cr12. Control System:- Japan Brand Delta PLC Control System With Touch Screen. Warranty:- One Year. Support:- Online. Installation:- On Site Free. Shipping:- All India Free. Training:- Free Onsite One Days. Usage / Application:- roll forming and roof sheet making | tin coating patra banana ke liye.

Price:- 1800000 ₹ + 18% GST 324000 ₹ Total Payable 2124000 ₹.

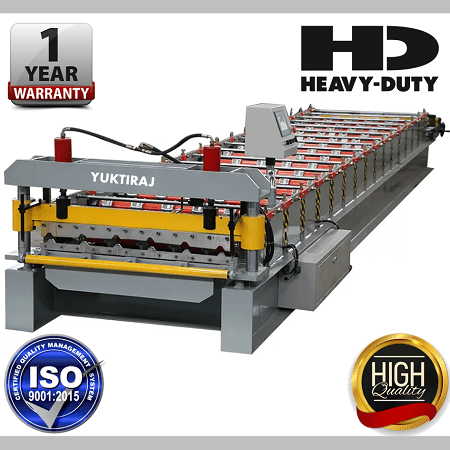

Model:- Yukti 304 High quality glazed sheet double layer roof press making machine roll forming machinery corrugated iron roofing sheet making machine best price in india.

Hello dear, Model Yukti 304 is a High-quality glazed sheet double layer roof press making machine roll forming machinery corrugated iron roofing sheet making machine best price in India. Yuktiraj Pvt Ltd is specialized in designing manufacturing import and export roll forming machines, Wall Panel roll forming machines, Roof Tile roll forming machines, Roofing Corrugated Sheet roll forming machines, With high-quality machines also good service, We have already established good business relations with many international customers and we also believe "low price, high quality first " Our commitment is high-quality and in-time delivery prompt service, our objective is customer satisfaction. Technical support for the whole machine life and free onsite training and free shipping for all India-free installations. If you buy other low-price profile roof sheet-making machines then you will have headaches every day because of terrible performance. A smart business entrepreneur always focuses on a high-quality machine because it's the main pillar of business. High-quality machines produce a high-quality product that is demanded in the market. Machine advantage: 1. PLC control to ensure high accuracy also easy operation. 2. Power saving that gives more profit. 3. Compact structure great looking save more space. 4. High output bit your competitor. 5. Low maintenance and simple to the operator. 6. Save labor only 1 people operate this machine. 7. Environment-friendly low noise. Click below the product catalogs button.

Technical Details

Model:- Yukti- 304. Suitable Material:- Galvanized Steel/Colored Steel Coil/G550. Feeding Width:- 1250MM. Roller:- 45# steel forged. Machine Size:- L*W*H 7.2m *1.45m *1.7m. Motor Power:- 3 Kw. Pump Station Power:- 3kw. Thickness Of Raw Material:- 0.3-0.8mm. Productivity:- 8-15m/Min. Diameter Of Shaft:- ¢70mm 45# steel forged. Forming Steps:- 15+13 stations. Weight:- Almost 4.5 Ton. Voltage:- 380V 50hz 3phases. Side Plate Thickness:- 14mm. Structure Of Machine:- 300 "H" Steel Welding. Transmission Way:- 1 Inch Chain Drive. Automatic Control System:- Delta PLC Made In Japan. Reducer:- 4# Planetary Ration1:59. Cutting Blade Material:- Cr12. Control System:- Japan Brand Delta PLC Control System With Touch Screen. Warranty:- One Year. Support:- Online. Installation:- On Site Free. Shipping:- All India Free. Training:- Free Onsite One Days. Usage / Application:- roll forming and roof sheet making | tin coating patra banana ke liye.

Price:- 3200000 ₹ + 18% GST 576000 ₹ Total Payable 3776000 ₹.

Tell Us Which Machine You Are Looking