Here are 4 screw piston press biomass sawdust corn stalk briquettes briquetting maker machine for sale low cost manufacturers Price in india

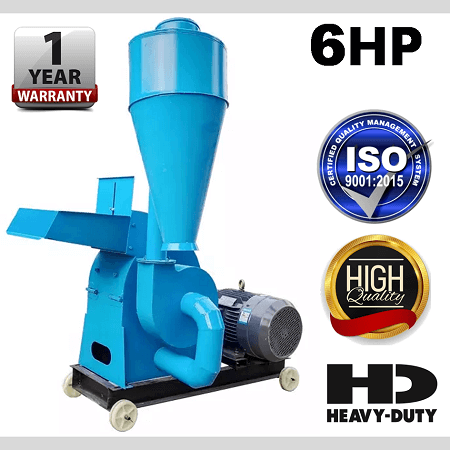

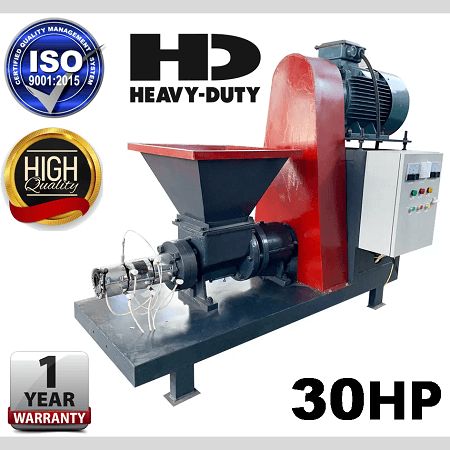

Model:- Yukti 407 best piston press Screw types biomass wood powder sawdust corn stalk briquetting briquettes maker machine for sale low cost manufacturers price in India.

The wood charcoal briquette press machine is also called a briquette forming machine. It is a very important process for making biomass charcoal. The biomass wastes such as bamboo, wood, shavings, fruit shells, and straw without any binder after high temperature and high pressure are extruded hexagonal shaped rods and ready for preparing the next carbonizing process. Biomass Charcoal briquette is an indispensable energy product in people's lives. It is widely used in metallurgy, medicine, the military industry, the chemical industry, environmental protection, and other industrial fields. It is also extensively used in civil fields such as food barbecue, hot pot, heating as well as animal husbandry. compare with traditional charcoal, machine-made wood charcoal has a regular shape, high density, uniform pores, large strength, good thermal conductivity, excellent electrical conductivity, flammability plus flame resistance, high heating value, especially smokeless as well as odorless, ash content during combustion The advantages of less as well as no pollution are well received and recognized by the market. Advantage: 1. the propeller is richly made of strong wear-resistant alloy, which the service life has been greater than before by 3-4 times. 2. Fully automatic control electric heating device, can freely adjust the dry furthermore humidity of the material, to make sure the stability of discharging molding. 3. Inflated feed port large output, high density of sticks. 4. Increase the inlet casting resources will not be blocked during the sawdust briquette making process. 5. Comprehensive rear propulsion propeller Easy to replace the propeller improves production efficiency. 6. The manufacture of the finished product density is larger, and forming efficiency is very high. 7. Enlarge the stability of equipment operation; gear meshing exactness is higher, and long service time. 8. It has the uniqueness of reasonable design, simple structure, convenient operation, reliable manufacturing quality, small volume, and less land cover, along with saving labor and electricity. 9. Reduced the friction between the machines along with the raw material, as well as increasing the density of the mandrel. Model Yukti 407 is a paramount piston press Screw types biomass wood powder sawdust corn stalk briquetting briquettes maker machine for sale low cost manufacturers price in India. For more about this machine please click on the product catalogs button or feel free to contact us.

Technical Details

Model:- Yukti 407. Dimension:- 1.9*0.68*1.6m. Production Capacity:- 400-450 Kg/H (Depend On Material). Weight:- 700 Kg. Motor Power:- 22 Kw. Heating Ring Power:- 6kw. Total Power:- 28kw. Voltage:- 380v 50hz. Moisture Of Raw Material:- Below 10%. Briquette Shape:- Hexagon. Diameter Of Briquettes:- 80mm. Inlet Particle Size:- Below 3mm. Pressure Type:- Screw Press. Working Temperature:- 320-350c. Labor:- Two For Each Machine. Color:- Gray Red. Material:- High Grade Carbon Steel. Warranty:- One Year. Shipping:- All India Free. Service:- Online. Usage / Application:- biomass wood powder sawdust corn stalk briquettes making.

Price:- 570000 ₹ + 12% GST 68400 ₹ Total Payable 638400 ₹.

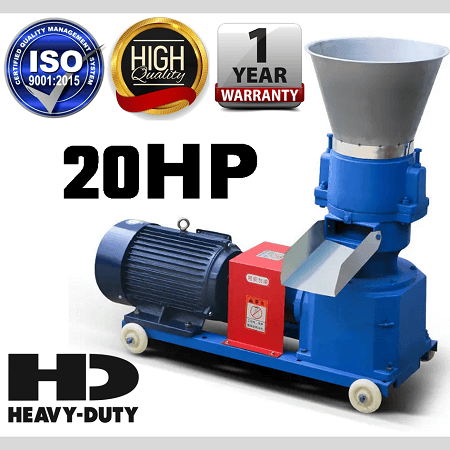

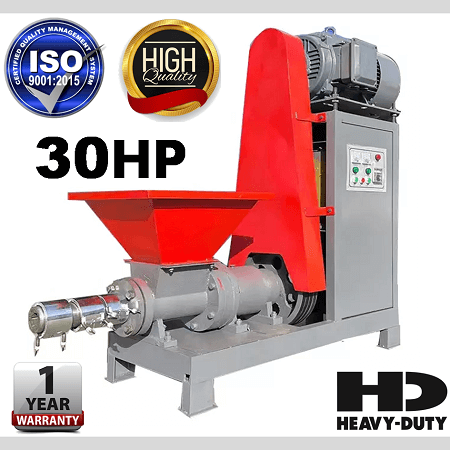

Model:- Yukti 406 Screw types piston press biomass sawdust corn stalk briquettes briquetting maker machine for sale low cost manufacturers price in india.

Biomass briquette making machine, also called sawdust briquette making machine otherwise waste wood recycling machine, recycles waste material such as rice husk, sawdust, peanut shell, corn straw, sorghum straw, soybeans straw, cotton straw, rapeseed, peanut, sunflower straw, chaff, grasses, sawdust, twigs, bark, bamboo shavings and extrudes the raw material into rod below the high squeezing pressure. The biomass briquette making machine makes full use of the waste raw material in a wood plant as well as forestry and solves the fuel shortage as well as protects the environment. Biomass screw extrusion briquette making machine adopts the screw extrusion principle in which biomass powder is extruded into a briquette. It is suitable for agriculture as well as forestry waste. This Corn Stalk Briquetting Maker Machine has Great product density, good combustibility, small volume, and alternative fuel for wood as well as coal as fuel, which also can be used as a carbonized substance. Advantages: 1. the product design is reasonable, the quality of the machine is reliable, small volume, covers a small area, simple structure, convenient operation, save labor, and less electricity cost. 2. The design of the automatic control electric heating device can adjust as per resources, to ensure the last production is stable, It can be improved. 1. The main parts of this product use a special wear-resistant substance, so it can continue production plus are durable. 2. It is appropriate for all kinds of biomass raw materials to form, with Low energy consumption furthermore high production efficiency. 3. Change the traditional machine spirit from three axletrees into four, which can boost the machine's stability and durability. 4. Reforming the old oil lubrication for oil-immersed lubrication, as long as no deficiency of oil, it can be used for a lot of years. 5. Increase the pitch as well as feed rate, thus very much increasing the product output. 6. Enhanced the structure of the molding drum, reducing the mechanical as well as the friction of the raw materials, and boosting the density of the mandrel. We give an Extra gift after buying a briquette machine 1 screw propeller, 1 taper sleeve, 3 welding rods, and 2 oil seals. Low maintenance Vulnerable part working time:- taper sleeve 45 to 60 days, long sleeve 150 to 180 days, screw propeller after seven days repair keeping using. Model Yukti 406 is the best Screw type piston press biomass sawdust corn stalk briquettes briquetting maker machine for sale at low cost manufacturers price in India. YUKTIRAJ PVT LTD was founded in 2019 located in Maharashtra. We produce different types of charcoal briquette making machine, and briquette machinery, namely, charcoal powder tablet molding equipment. We have exported to more than 26 countries and India. We have passed ISO9001:2015 quality system certification. It is our mission to provide the most excellent quality products as well as the most excellent service for every customer. For more about this machine please click on the product catalogs button or feel free to contact us.

Technical Details

Model:- Yukti 406. Dimension:- 1870*720*1450mm. Production Capacity:- 300 Kg/H (Depend On Material). Weight:- 750 Kg. Motor Power:- 22 Kw. Heating Ring Power:- 6kw. Total Power:- 28kw. Voltage:- 380v 50hz. Moisture Of Raw Material:- Below 10%. Briquette Shape:- Hexagon. Diameter Of Briquettes:- 80mm. Inlet Particle Size:- Below 3mm. Pressure Type:- Screw Press. Labor:- Two For Each Machine. Color:- Gray Red. Material:- High Grade Carbon Steel. Warranty:- One Year. Shipping:- All India Free. Service:- Online. Usage / Application:- biomass wood powder sawdust corn stalk briquettes making.

Price:- 395000 ₹ + 12% GST 47400 ₹ Total Payable 442400 ₹.

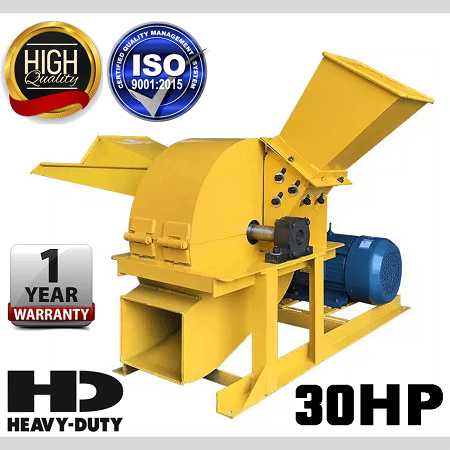

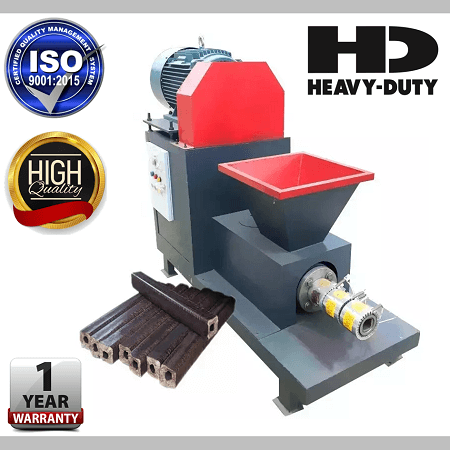

Model:- Yukti 314 Screw types piston press biomass sawdust corn stalk briquettes briquetting maker machine for sale best price in india.

Model Yukti 314 is the most excellent Screw types piston press biomass sawdust corn stalk briquettes briquetting maker machine for sale best price in India. Briquettes are made by grinding Biomass sawdust into a homogeneous pulp also forming this into a briquette under very elevated pressure. Elevated pressure also pressing releases one of the natural components of wood lignin which has the property of becoming liquid at high-pressure temperature also as it subsequently cools it binds the wood jointly in its new form Briquettes. After the dispensation of drying, and compressing under high pressure also temperature, the biomass briquette is characterized by high density, better combustion, small in size, and capable as a substitute for the superior coal otherwise firewood. This bio-fuel briquette is 45-80mm in diameter and occurs in the hollow quadrangular otherwise hexagonal cylinder otherwise hollow hexagonal with a 15-20mm hole during the body. The bio-fuel carbon maintains cleanliness plus hygiene and is apposite for family heating and barbecuing. Features: 1. This Screw types piston press biomass sawdust corn stalk briquettes briquetting maker machine makes bio-fuel briquette is 50mm in diameter occurs in the hollow quadrangular otherwise hexagonal cylinder otherwise hollow hexagonal with a 15-20mm inner-hole. 2. Square, hexagonal, pentagon, pentagon with the edge, hexagon with edge shape available for this Screw types piston press biomass sawdust corn stalk briquettes briquetting maker machine. front diameter available 50mm, 55mm, 60mm, 65mm, 70mm, 80mm. you can select any of them. If the row material is too big we will recommend you crusher it's we have crusher machine. As well the row material size must be less than 3mm and the moisture of the material should be 12% Too wet or too dry will cause a bad forming effect. We have a sawdust dryer machine if you need to the abject moisture level. Raw material: Peanut shell, Sawdust, Little branch, Corncob, Bagasse, Rice husk, Leaves, Logs, Palm kernel, Nuts shell, Straw, Cotton stalk, Bamboo, etc. The working principle of this Screw types piston press biomass sawdust corn stalk briquettes briquetting maker machine is sawdust was put into the machine the screw will push the row material into the sleeve. After high temperature also high pressure and the raw materials are extruded into different shapes. Screw types piston press biomass sawdust corn stalk briquettes briquetting maker machine advantage: 1. the machine adopts excellent quality carbon steel the service life over 11 years. 2. Pure copper-made high-grade motor. 3. Save electricity save labor save time and boost production. 4. Environment-friendly operator friendly. 5. Essay to use low maintenance. 6. Briquettes are featured with extended burning time and great firepower. 7. Its advanced new generation Screw types piston press biomass sawdust corn stalk briquettes briquetting maker machine. 8. Featured with simple structure, small size, convenient operation, covering little space. 9. Equipped with an automatic electric heating mechanism, the row material humidity can be accustomed at all times to ensure the molding effect. 10. The main parts of the Screw type piston press biomass sawdust corn stalk briquettes briquetting maker machine are made of wear-resistant material with a specific treatment that can ensure continuous production also durability. 11. Screw types piston press biomass sawdust corn stalk briquettes briquetting maker machine is equipped with bearings, improving the stability also durability of the machine. 12. Distended screw pitch can increase the feeding amount and also improve the yield. 12. Superior forming cylinder arrangement can reduce the friction between the machine and raw materials and also increase the density of briquettes. Why you will select Yuktiraj Pvt Ltd for Screw types piston press biomass sawdust corn stalk briquettes briquetting maker machine? Here are some valid notes 1. We offer full operations online training. 2. We have a dedicated support system our support is on every day even on holidays. 3. We offer one year warranty and all India free shipping. 4. Our company is passing out the ISO quality management system. 5. We are a head in steel work machines in India. 6. We have a most excellent brand reputation you can check Google. 7. We are selling all types of machines that require this biomass sawdust corn stalk briquettes making business you do not need to go anywhere. 8. Our company gives you a 0% fraud guarantee today on the web thousand of fraudsters immediately; your hard earned money is safe with us. 9. We are professionals in producing and selling Screw types of piston press biomass sawdust corn stalk briquettes briquetting maker machine. 10. We have a superior quality control system also we carefully test every machine before delivery. 11. On-time delivery and safe delivery is our promise. For more about this machine kindly check the product catalogs button to get more info.

Technical Details

Model:- Yukti 314. Dimension:- 1.68*0.72*1.25m. Production Capacity:- 200-250 Kg/H (Depend On Material). Weight:- 700 Kg. Motor Power:- 15 Kw. Heating Ring Power:- 4kw. Total Power:- 19kw. Voltage:- 380v 50hz. Moisture Of Raw Material:- Below 10%. Briquette Shape:- Hexagon. Diameter Of Briquettes:- 50mm. Inlet Particle Size:- Below 3mm. Pressure Type:- Screw Press. Working Temperature:- 320-350c. Labor:- Two For Each Machine. Color:- Gray Red. Material:- High Grade Carbon Steel. Warranty:- One Year. Shipping:- All India Free. Service:- Online. Usage / Application:- biomass wood powder sawdust corn stalk briquettes making.

Price:- 390000 ₹ + 12% GST 46800 ₹ Total Payable 436800 ₹.

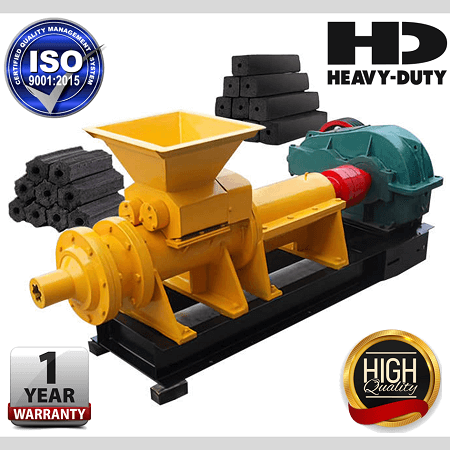

Model:- Yukti 421 best biomass wood powder Wood charcoal sawdust Briquette Extruder Machine maker machine for sale low cost manufacturers price in India.

This sawdust Briquette Extruder machine is a device that uses sawdust, straws, rice husks, branches, and other wood powder materials to make rod-shaped solid fuels under high pressure as well as high-temperature conditions. High Pressure furthermore High Briquetting Efficiency This briquetting machine is specially designed with four rollers that can enlarge equipment pressure and get better briquette making efficiency. In accumulation, a hydraulic device can be an alternative if required. Energy Saving, as well as Environment Friendliness The press briquette maker machine, is mainly used to press powdery industrial wastes as well as dust to regularly shaped briquettes for further usage, reducing dust pollution as well as improving the resource utilization ratio. It can run on low power so saving much energy. Thanks to together with this construction; the Briquette Extruder machine will not cause air along with noise pollution. Wide Application as well as Low Requirement for Working Environment the industrial waste processing machinery is appropriate for use in all countries around the world. Moreover, it can be used in all kinds of severe environments, for example extremely cold weather, high temperature, etc. Easy Installation along with Simple Transportation This briquette making machine is designed with a high-strength carbon steel plate as its support, enabling it to be directly used on the tough flat area without having to build a foundation. Additionally, it is easy for users to transfer furthermore transport this equipment. Trouble-free Operation and Easy Maintenance. The industrial fuel sawdust briquetting machine is available in 40hp high and stronger power. Low labor as well as simple operation In daily use, you only need to do standard maintenance according to the maintenance training. Advantages: 1. This machine come with reasonable design, simple structure, reliable quality, convenient operation, small size, small occupation area, plus electricity saving. 2. Special wear-resistant material durable longer life span. 3. Appropriate for all kinds of raw materials of biomass briquetting. 4. Improved adding one bearing into the traditional ones, which makes the machine more stable as well as durable. 5. Enhanced from basting to immersing. 6. The pitch has increased to get better the amount of feed to greatly improve the output. 7. The operation is stable as well as convenient. The inside of the sawdust rod-making machine is equipped with a super-conduit, which makes the heat energy boost quickly and quickly, plus greatly improves the heating time. Model Yukti 421 is paramount biomass wood powder Wood charcoal sawdust Briquette Extruder Machine maker machine for sale at low cost manufacturers price in India. For more about this sawdust Briquette Extruder machine please click on the product catalogs button or feel free to contact us.

Technical Details

Model:- Yukti 421. Dimension:- 1.96*0.9*1.8m. Production Capacity:- 450-500 Kg/H (Depend On Material). Specific Gravity Density:- 1100~1400kg/M3. Calorific Value:- 6000-7500kcal/Kg. Weight:- 700 Kg. Motor Power:- 30Kw 40hp. Heating Ring Power:- Total 3 Ring 6kw. Total Power:- 36kw. Voltage:- 380v 50hz. Moisture Of Raw Material:- Below 12~15%. Briquette Shape:- Hexagon. Diameter Of Briquettes:- 80mm. Inlet Particle Size:- Below 3mm. Pressure Type:- Screw Press. Working Temperature:- 320-350c. Labor:- Two For Each Machine. Color:- Gray Red. Material:- High Grade Carbon Steel. Warranty:- One Year. Shipping:- All India Free. Service:- Online. Usage / Application:- biomass wood powder sawdust corn stalk briquettes making.

Price:- 590000 ₹ + 12% GST 70800 ₹ Total Payable 660800 ₹.